Are you ready to catapult your manufacturing processes into the future? Artificial Intelligence (AI) is no longer just a buzzword – it’s a powerhouse tool that’s reshaping the industrial landscape. In this article, we’ll dive deep into how embracing AI in manufacturing can unlock unprecedented levels of efficiency and innovation. Get ready to transform your operations and stay ahead of the competition!

Introduction: The AI Revolution in Manufacturing

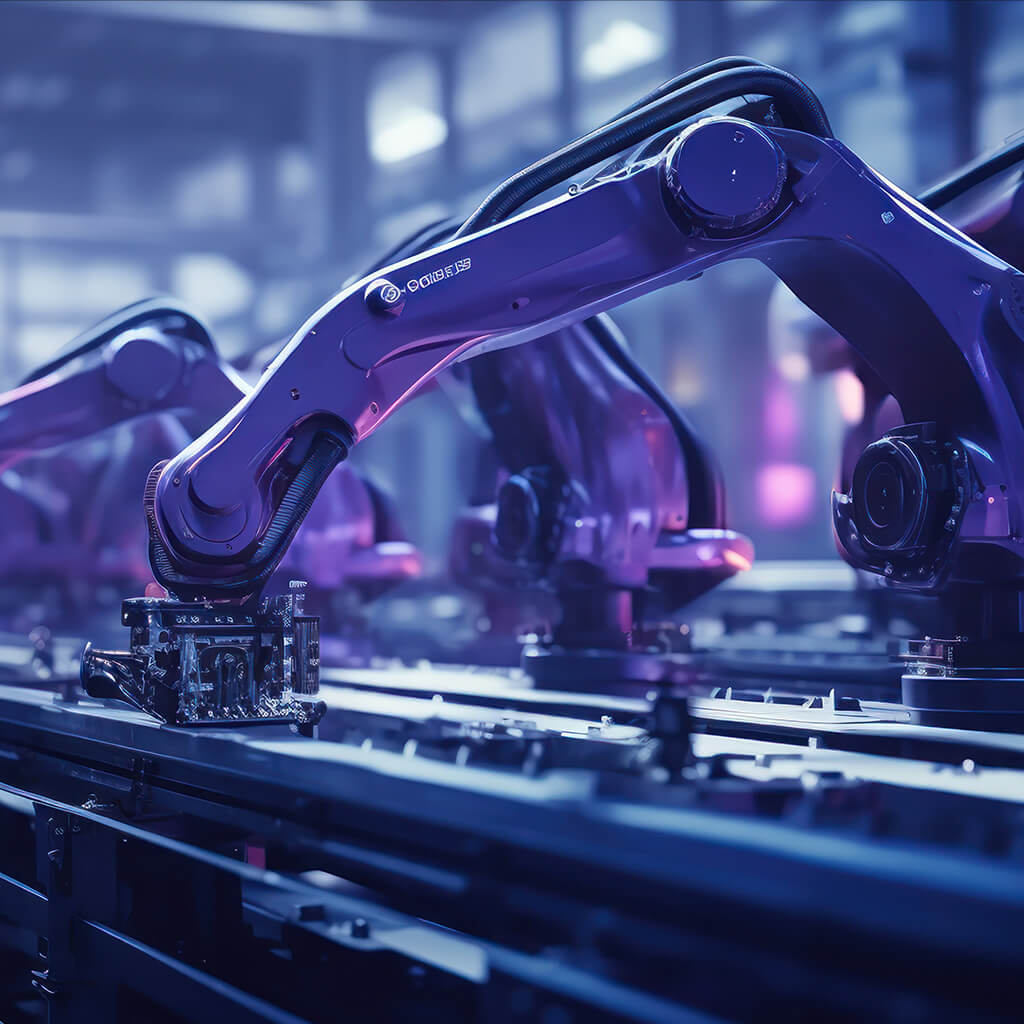

Picture this: a factory floor where machines predict maintenance needs before breakdowns occur, where production lines adjust themselves in real-time for optimal output, and where quality control is so precise that defects are virtually eliminated. This isn’t science fiction – it’s the reality of AI-powered manufacturing, and it’s happening right now.

The manufacturing sector is on the cusp of a technological renaissance, with AI at its core. From small workshops to sprawling industrial complexes, businesses are discovering that AI isn’t just an option – it’s a necessity to remain competitive in today’s fast-paced market.

7 Transformative Applications of AI in Manufacturing

1. Predictive Maintenance: Say Goodbye to Costly Downtime

One of the biggest headaches in manufacturing is unexpected equipment failure. AI changes the game by analyzing vast amounts of data from sensors to predict when machinery is likely to fail. This allows for maintenance to be scheduled during planned downtime, dramatically reducing costly interruptions.

Did you know? According to a report by PwC, predictive maintenance can reduce costs by 12% and improve uptime by 9%.

2. Quality Assurance: Perfection at Machine Speed

AI-powered visual inspection systems can detect defects with superhuman accuracy and speed. These systems learn from each inspection, continuously improving their ability to spot even the tiniest imperfections.

Pro tip: Implementing AI in quality control can reduce defect rates by up to 90%, according to a study by McKinsey & Company.

3. Supply Chain Optimization: Streamline Your Operations

AI algorithms can analyze complex supply chain data to optimize inventory levels, reduce waste, and improve delivery times. By predicting demand fluctuations and potential disruptions, AI helps manufacturers stay one step ahead.

4. Energy Management: Boost Sustainability and Cut Costs

Smart AI systems can monitor and control energy usage across manufacturing facilities, optimizing consumption patterns and reducing waste. This not only cuts costs but also helps companies meet sustainability goals.

5. Generative Design: Unleash Creativity and Innovation

AI is changing the game in product design. Generative design tools can create thousands of design options based on specific parameters, allowing engineers to explore innovative solutions they might never have conceived on their own.

6. Collaborative Robots (Cobots): Human-Machine Teamwork

Cobots are AI-powered robots designed to work alongside humans safely. They can handle repetitive or physically demanding tasks, freeing up human workers to focus on more complex, value-added activities.

7. Process Optimization: Fine-Tune Your Production

AI can analyze every step of the manufacturing process, identifying bottlenecks and suggesting improvements. This leads to smoother workflows, reduced waste, and increased overall efficiency.

Frequently Asked Questions About AI in Manufacturing

Q: Is AI in manufacturing only for large companies?

A: Not at all! While large companies may have been early adopters, AI solutions are becoming increasingly accessible to small and medium-sized manufacturers. Cloud-based AI services and scalable solutions mean businesses of all sizes can benefit from this technology.

Q: Will AI replace human workers in manufacturing?

A: Rather than replacing workers, AI is changing the nature of manufacturing jobs. While some repetitive tasks may be automated, AI creates new roles focused on managing and maintaining AI systems, data analysis, and more complex problem-solving.

Q: How quickly can I see results from implementing AI in my manufacturing processes?

A: The timeline for seeing results can vary depending on the specific application and the scale of implementation. However, many companies report seeing significant improvements within months of adopting AI solutions, particularly in areas like predictive maintenance and quality control.

The Future of AI in Manufacturing: What’s Next?

As AI continues to evolve, we can expect even more exciting developments in manufacturing:

- Digital Twins: Virtual replicas of physical manufacturing systems that allow for real-time monitoring and simulation.

- Autonomous Factories: Facilities that can operate with minimal human intervention, optimizing themselves in real-time.

- AI-Driven R&D: Accelerated product development cycles through AI-powered research and testing.

Conclusion: Embrace the AI Revolution

The integration of AI in manufacturing isn’t just about staying current – it’s about propelling your business into a future of unparalleled efficiency and innovation. By embracing AI technologies, manufacturers can:

- Dramatically reduce downtime and maintenance costs

- Improve product quality and consistency

- Optimize supply chains and inventory management

- Boost energy efficiency and sustainability

- Accelerate product development and innovation

The question isn’t whether you should adopt AI in your manufacturing processes, but how quickly you can implement these game-changing technologies. The future of manufacturing is here, and it’s powered by AI. Are you ready to lead the charge?